How Fossil Fuels can Accelerate the Transition to a Sustainable Renewable Energy Infrastructure.

By utilizing the waste created in the production of oil, the United States can build a domestic supply chain for the lithium needed for electric vehicles.

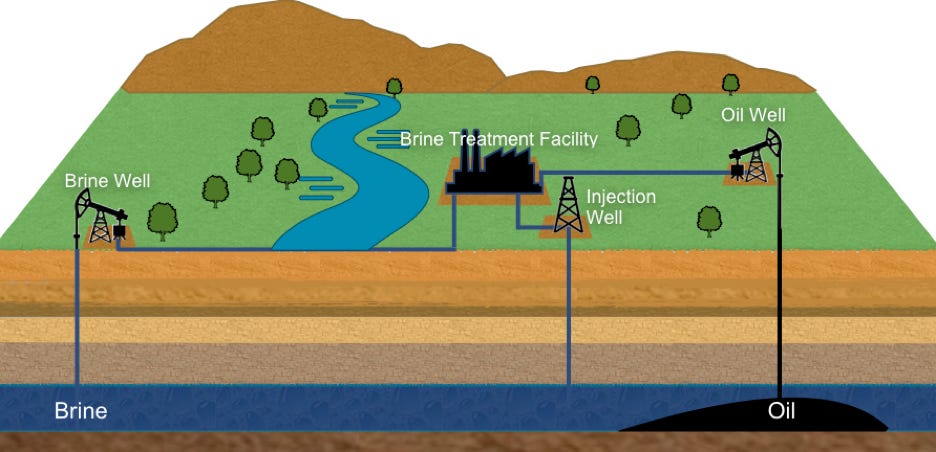

As oil and gas resources are harvested, a naturally occurring brine is pumped to the surface alongside the hydrocarbons from the reservoir. For the better part of a century, oil and gas companies have simply discarded a substantial portion of this brine as waste. Globally, 250 million barrels of this brine are pumped to the surface every day and constitute a major waste stream generated in the hydrocarbon industry. However, as the world transitions to a sustainable energy infrastructure and with ongoing efforts by the United States to secure domestic supplies of battery metals, wastewater created by oil and gas extraction, referred to as produced water in the industry, is now being looked at as a valuable resource. Extracting lithium from produced water and directly from oilfield brines would not only alleviate the imbalance between supply and demand forecasted for the lithium-ion battery industry, but would also create new revenue streams for the oil and gas sector and reestablish economic growth in communities that once depended on the hydrocarbon industry for their livelihood.

As wells age, there is a decrease in oil and gas production and a significant increase in produced water. Produced water can reach as high as 98% of the total volume from mature wells. This has created a growing demand in the industry for the environmentally sustainable management and reuse of produced water. In 2022, Prairie Lithium was approached by a Saskatchewan-based oil and gas company with a list of wells they planned to abandon. The wells were sold for $1 per well. This deal saved the oil and gas company the cost of abandoning the wells and saved Prairie Lithium the cost of drilling entirely new wells; in the case of oilfield brines, industrial infrastructures once used for the production of hydrocarbons can be repurposed for the extraction of lithium.

The continued operations of mature wells have both direct and indirect economic benefits to the local communities that would have been negatively impacted by the closure of those wells. This will be in the form of tax revenue and commerce with local businesses, expansion of local infrastructures to support the lithium-ion industry, and the direct benefit of transitioning jobs to the extraction of lithium instead of eliminating them when the well is abandoned.

Side Note: While lithium can be extracted from brines found at oil, gas, and shale gas projects, for simplicity, oilfield brines and produced water will be used as the designations for all kinds of wastewater created in the hydrocarbon industry in this article.

Petrolithium

In North America, estimates show that at the start of operations, for every unit of oil and gas produced, three to four units of brine are pumped. Throughout the life of the well, the ratio of brine grows until the well is decommissioned. Containing less than 1% hydrocarbons but a much higher concentration of lithium, this brine gave rise to a term created by Canadian firms in the mid-2010s called petrolithium, who were looking for profitable and environmentally viable alternatives to the standard practices of abandoning oil and gas wells.