While doing my morning search for lithium news I came across one about a DLE system that was proclaiming some rather amazing figures.

“New plant produces lithium 500 times faster with 96% recovery rate from brine.”

The article discusses an adsorbent-based DLE platform developed by Schlumberger Technology Corporation (NYSE: SLB), which includes the pretreatment, concentration, purification, and lithium precursor stages. While packaging all stages of a DLE system isn't new, for every complete DLE package, there are at least five startups that focus solely on pretreatment, brine concentration before extraction, or lithium precursor production. However, SLB did not invent this DLE (originally, a solvent extraction was proposed for the pilot plant); rather, they are using a DLE platform called ILiAD, developed by ILiAD Technologies, a subsidiary of EnergySource Minerals (ESM). This is the same DLE platform being used at ESM’s Salton Sea Project. Arcadium Lithium (NYSE: ALTM) is also a minor stakeholder in ESM, which gives them the right to deploy the ILiAD platform at its brine resources.

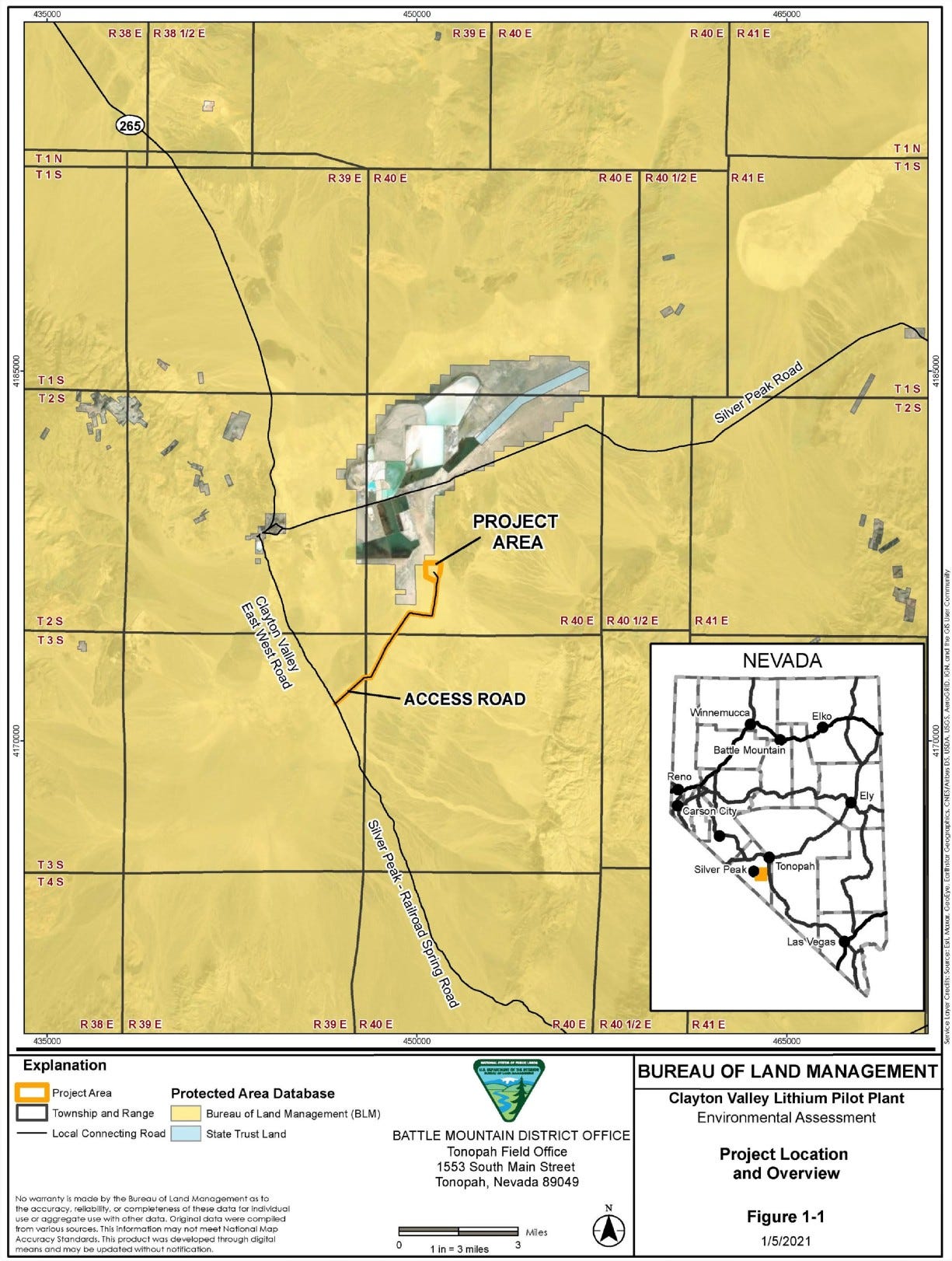

The pilot plant is located in Clayton Valley, Nevada, where Silver Peak, the only operational lithium mine in the United States, is also located. Outside of the Smackover Formation in Arkansas and projects in the Lithium Triangle in South America, you don’t often hear about DLE projects like this, especially those being tested with continental brines. There is also a very interesting earn-in agreement between the claims owner and SLB, which I discuss below. But first, I want to address the misleading characterization of the DLE technology.